1. TRUSUB™ TOOL

The high-strength steel construction integrates and protects the precision sensors measuring the drilling parameters used to generate valuable productivity insights.

2. OPERATOR INTERFACE PANEL

The operator interface combines rich text and dynamic visualizations with live drilling parameters streaming wirelessly from the TruSub tool.

All parameters are viewable by the operator in real-time at the rig controls and retained for further processing.

3. REMOTE VIEWING WITH DRILLING INSIGHTS

The remote viewing functionality allows both the operator and geologist real-time access to drilling parameters and productivity metrics. Operator inputs and TruSub tool outputs combine to provide a comprehensive depth-based log of each hole.

Powerful filtering functionality makes finding the useful information easy.

UNDERSTAND THE DATA

Operators see real-time drilling parameters directly from the rod string, providing a firm baseline to improve on personal performance.

SET TARGETS

Lock in parameters that work or fine-tune adjustments on the fly. Setting parameter thresholds enables at-a-glance visual feedback to alert operators when corrective actions on the rig are needed to maintain optimal drilling.

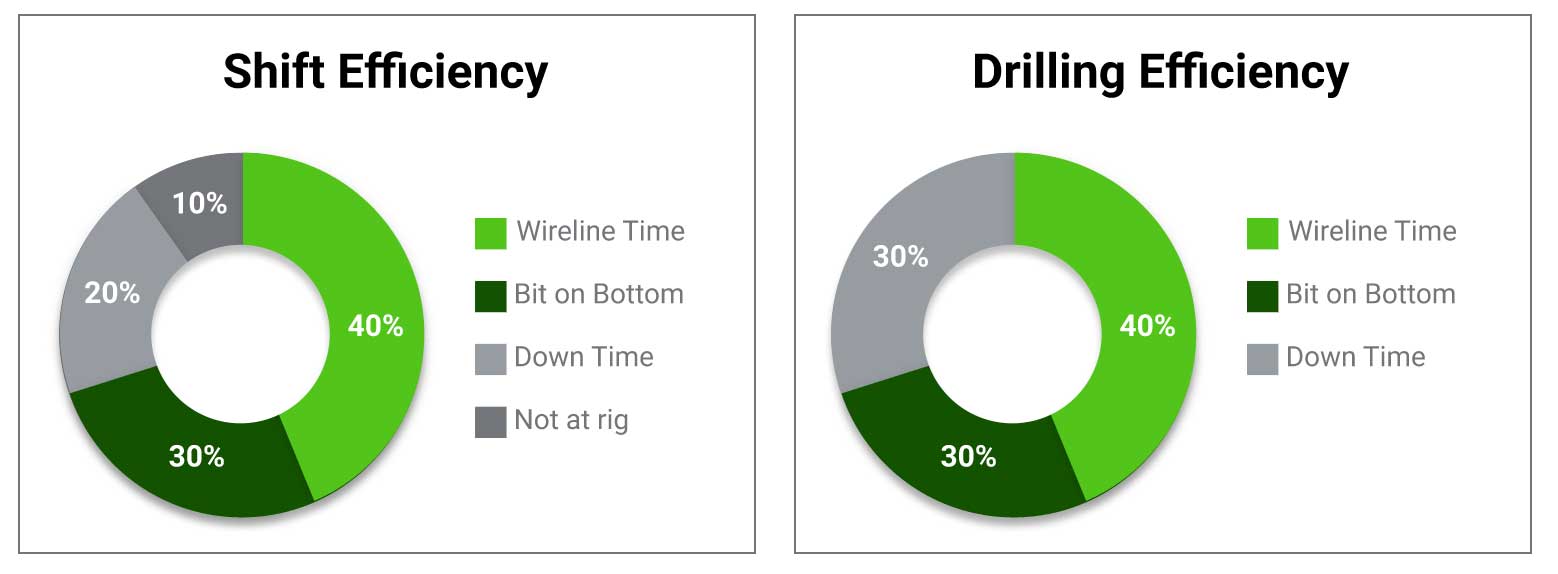

MEASURE THE IMPROVEMENTS

Powerful visualizations driven by the TruSub sensor data enable key measurements of field operation parameters needed for continuous improvements.

COMPARE SHIFTS AND RIGS

Better understand the drilling techniques and equipment that work and the ones that don’t. Share winning strategies and techniques across shifts and crews to maximize performance.

SECURE IN THE CLOUD

All data is hosted in a secure, encrypted cloud environment using access permissions to ensure your data is safe.