SAFETY

September 18, 2017

Keeping new starts safe as the market rebounds

This article originally appeared in Australian Mining.

As the market starts to rebound, the number of new starts in the industry rises, and as a result, safety incidents can follow that curve. New hires on drill sites are at the biggest risk for safety incidents. They’re inexperienced, unaware of hazards, nervous, eager to prove themselves and generally less mindful of all the risks on a drilling site and the impact of potential incidents, injuries and near misses.

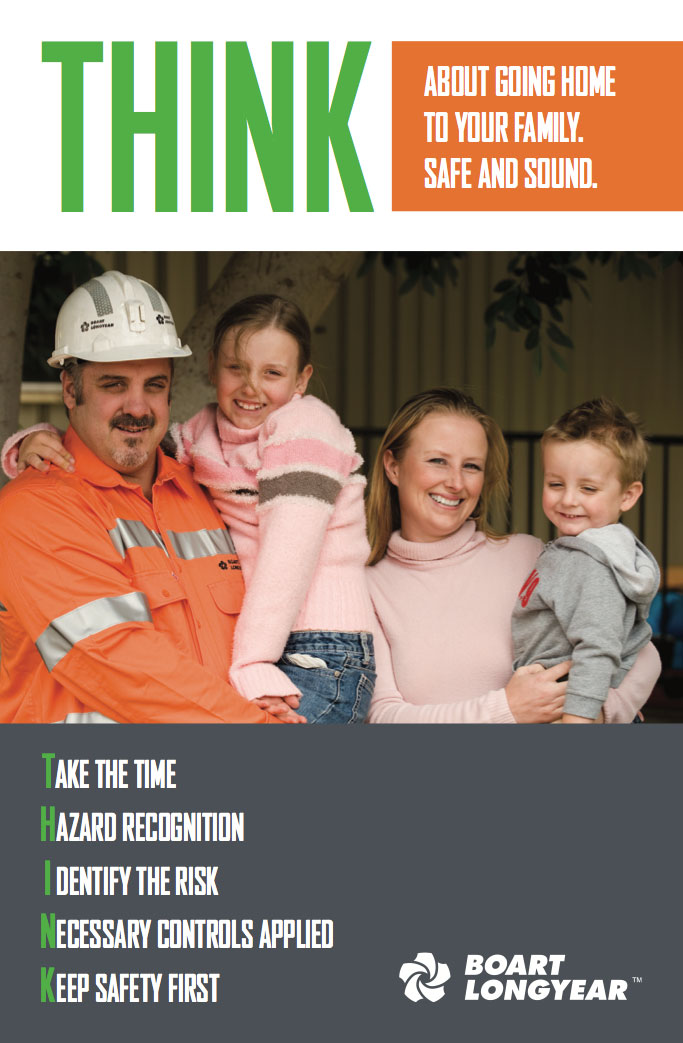

In the first 90 days, Boart Longyear new hires are required to learn global safety programs like THINK (Take the time, Hazard Recognition, Identify the risk, Necessary controls applied, Keep safety first). They’re trained in how to conduct field-level risk assessments and why they’re so important before undertaking any task.

New hires learn the Golden Rules of Safety and the Rules of the Road and are required to complete a standardized induction training in our online integrated training management system. They also complete an interactive training workbook with the help of a mentor and a driller – all part of the 90-day Green Hat program at Boart Longyear. Green hard hats indicate a new start so that everyone onsite can take extra care and look out for our newest employees. The objective of all of these safety programs is to ensure that every employee goes home safe.

Ideally, safety programs also ensure that wherever a Boart Longyear driller or offsider goes to work, the client can expect the same safe results. That’s a big reason our clients choose us. Our safety commitment, culture and programs align with their own, and client-specific programs are easily embedded as Boart Longyear employees are well-versed in adopting and working with the highest safety standards.

The Boart Longyear™ Drilling Services team in Australia is taking extra steps above and beyond to ensure new starts are safe and quickly adapt to the safety culture at Boart Longyear. It takes more than just great safety programs to show what a great safety culture looks like and to help new starts understand how to be a part of it. It’s really about changing the way people typically think about working and completing tasks.

The Ten Steps to Working Safely are basic instructions for applying the Golden Rules of Safety. Essentially, this checklist is a guide through the planning process, providing triggers on what needs to be talked about regarding the task, checking the equipment, preparing the area and the personnel, controlling all of the energy – including removing any stored energy, completing a final check and then on step seven, starting the task.

When launching into a task straight away without any planning, usually trying to keep up meters and billable hours, without all the preemptive steps – that’s when incidents occur. There are many steps to complete prior to beginning any task. And don’t skip the debrief process, that’s another critical step, discussing what worked and what didn’t work in order to identify and implement changes.

A lot of incidents are a result of poor planning, poor communication, and perceived time pressure. Perceived time pressures can be prevalent in the industry. When contractors charge clients by the meter or hourly rates, there are usually key performance indicators (KPIs) written into the contract. When a crew is being measured by those KPIs, then those KPIs can drive behaviors. The crews, including supervisors, think they’re doing the best thing for the company trying to meet KPIs vs. working slower and safely. At Boart Longyear, supervisors and drillers and offsiders are encouraged to slow down and think about the things that could possibly prevent them or their colleagues from going home safely.

During a recent safety pause, the team in WA conducted a communication exercise where crews were blindfolded and one designated person attempted to instruct the rest on what they were observing, basically folding a piece of paper. Pretty simple paper folding task – only four steps, but the outcome shows how much we think we’ve communicated when indeed the message is not getting across.

Towards the end of the exercise, time pressure was added by comments like, “Hurry up, we have to get this done!” The reaction of the participants? They started to rush and get the job steps wrong. Imagine if they were using heavy equipment!

We debriefed to discuss how this relates to what happens onsite - how time pressures can stress anyone out, even if they’re just folding a piece of paper and how that translates in the field where mitigating risk is critical. During the debriefing the question was posed, “Why didn’t anyone stop the job?” It also makes a difference to tell subordinates and work mates when they’re doing a good job, so positive behaviors are reinforced and that feeds their motivation to continue to work safely.

The point of the safety pause was to reinforce the importance of consultative feedback, asking questions, praising positive behaviors, and stopping the job when it’s getting stressful. Communication and leadership development are opportunities to improve safety and especially the safety of new starts.

It’s also important to encourage supervisors and drillers to ask new start employees more questions. Too often, a driller or supervisor will just talk at a new start or read off a JSEA and the new start’s brain switches off, they’re not paying attention or following. Supervisors and drillers have to ask open-ended questions to switch on their thinking brain. When working with new starts, it’s not sufficient to ask, “Do you understand mate?” A green hat is going to say yes, they don’t want to let you down.

After training a new start on a task, ask them to describe it, “So how are you going to establish this exclusion zone?” Making them explain it to you in their own words confirms understanding and mitigates the risk of them agreeing and then blindly going about a task in an unsafe manner. Also, empower them to ask questions. It makes a better impression when they ask instead of making assumptions. When you reinforce that asking questions demonstrates they’re committed to safety, want to understand the directions and to learn, they’re more likely to speak up when they have questions.

There’s always going to be an inherent concern with a growing number of new starts, as we commence recovering from an industry downturn. At Boart Longyear we are committed to increasing training, communication and focusing on what’s most important – safety. It’s up to all of us to look out for the next generation of drillers and offsiders.

WATCH

Watch the Boart Longyear Make it Safe | Make it Personal | Make it Home video

WATCH VIDEO

[pardot-form height="770" id="2391" title="Watch Make It Safe Video"]