FIELD TIPS

April 1, 2017

Drill rod threads: tips to avoid common problems and improve productivity

When you own a car, you learn that a little preventative maintenance goes a long way in ensuring it stays in good shape and runs well over many years. The same principle applies to drill rods. With proper use and handling in the field, drill rods will last longer, give you better results and ultimately lead to lower operational costs.

Consider that rods typically make up 3 percent of total drilling costs. But if a rod fails prematurely or unexpectedly, it can mean a significant jump in those costs. For example, re-drilling a hole for one month can increase costs by 9 percent.

The good news is that, with the right care and handling routine for your rods, you can avoid those setbacks and keep your drilling operations productive. Be sure to inspect your rods or accessories regularly for excessive wear and discard those that are too damaged. Here’s a look at the reasons rods fail prematurely and ways to avoid those problems.

Thread wear

The wear from sliding steel-on-steel surfaces, or galling, is the most common way rods fail. This wear comes from the adhesion that occurs when mating surfaces have similar hardness; the rate of adhesion wear decreases as the surface hardness increases. While some wear can be tolerated without compromising performance, worn surfaces are prone to further wear. Excessive contact or sliding pressure or damaged accessories can accelerate the problem. Unattended, the degree of wear can worsen to the point where it can cause early failure or even seize the joint.

Thread compound is critical to the life of a joint. A poor choice of compound or diluted compound can provide insufficient friction or allow the mating surfaces to interact, resulting in adhesive wear.

- Clean and lubricate joints regularly, preferably after every break.

Compounds containing 50 percent zinc particulate generally provide a higher friction factor and better resistance than those containing copper, lead or graphite particulate. - Choose joints with mating surfaces of dissimilar hardness.

Studies show that a system with dissimilar hardness can extend useful life several times over one with similar hardness. Boart Longyear’s patented RQ threads undergo a unique case-hardening process whereby the pin end is strengthened to prevent adhesion wear. With regular care, the RQ thread shows minimal wear after 60 make/break cycles, compared with competing threads that show obvious wear after 30 make/break cycles. - Inspect and replace damaged or worn accessories.

- Reduce thread contact pressure by adjusting feed rate and/or rotation speed.

Fatigue and cracking

Fatigue failures are brittle failures or cracks that occur under stress or load levels that are significantly below static load ratings but are applied or cycled a large number of times. An example is a rod string rotating in a deviated hole.

There are many other reasons for fatigue failures or cracked pins or boxes. Severe stabbing when inserting a pin into a box end can compromise the fit of the joint and cause fatigue failures. Joints may not be closed properly due to insufficient make-up or an excessive stand-off gap. Threads can be deformed from overload or excessive loads, hammering, foreign debris, or wear debris in the joint. Poor-quality thread compound or worn accessories can also cause accelerated wear.

- Clean threads of excessive foreign or wear debris.

- Use hydraulic tools to apply the minimum make-up torque required.

- Only use non-damaging tools (e.g. rubber mallet) when breaking rod joints

- Reduce deviation, drilling loads and/or pullback.

- Improve lubrication of the string.

Consider upgrading your thread compound. - Do not mix rods from different manufacturers.

Doing so may cause equipment failure and operator injury.

Box wear

Similar to the steel-on-steel wear of the joints, the box end of the joint is subject to abrasive wear against the wall of the drill hole. As the box end decreases in thickness, the load capacity of the joint is reduced.

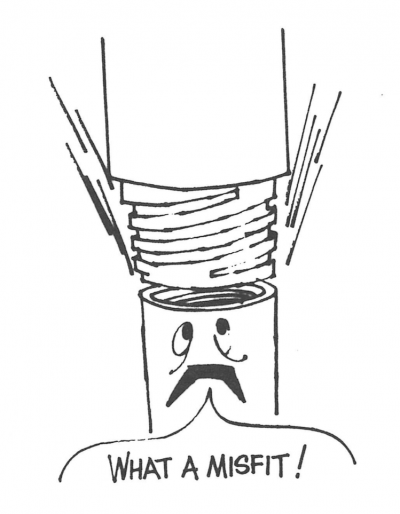

Wear can also be due to incorrect torque used when connecting the joints. Insufficient force can lead to cracking, while excessive force can lead to bulging, as the shoulder flares or rolls over. Joints with insufficient make-up will begin to leak as pullback load increases and the shoulder relaxes.

- Monitor the load capacity of the joint.

A gauge, such as Boart Longyear’s “go/no go” gauge, can determine whether a portion of the shoulder has retained the majority of its original thickness and corresponding load capacity. - Apply the appropriate amount of additional make-up torque.

As a rule of thumb, the make-up torque on each joint should be adjusted to match the expected drilling torque.

Midbody wear

As load or rotation increases, the contact pressure between the string and the hole or casing wall increases, contributing to wear on the midbody.

Hole deviations increase the contact pressure and friction between the string and the hole. High pullback or thrust load combined with high rotation speed can also increase contact pressure and friction. You will notice a polished spot from heavy wear in a spiral pattern on one side of the string.

- Improve lubrication of the string.

Rod grease is often used to reduce friction. Alternatively, drilling fluids can be used. - Reduce drilling loads, pullback or rotation speed, or repair the hole.

- Consider upgrading to stronger rods.

Specialized processing doubles the bend strength of the midbody on Boart Longyear rods.

Bending

Bending stresses increase under high load or rotation, especially in oversized or deviated holes or caves, and may cause permanent bending of the string. Bent rods lead to increased contact pressure and friction against the hole or casing wall, evidenced by increased vibration and torque. Many factors contribute to rod bending, including RPMs, lubrication, hole angle, casing or bit size, and vibration.

- Lubricate properly.

Fluid dampens vibration and reduces friction, which helps prevent bending. - Minimize vibrations.

Consider adjusting the speed. Changes as small as 50 RPM can produce significant reduction. - Do not exceed deviation ratings.

- Plan deviations for portions of the string under low pullback.

- Consider using stronger joints for higher load capacity or lightweight rods for reduced stiffness.

Leakage

Leakage is often an early indication of one of the above problems. For example, if the pin is not aligned when inserted into the box end, it will stab into the shoulder, causing permanent damage and resulting in leakage. Other reasons for leakage include joints that are not closed properly or have an uneven fit, pins or box shoulders that have been damaged in handling, or threads or shoulders that are significantly worn or deformed from excessive load.

In summary, many of the problems that cause rods to fail can be prevented with a few straightforward steps. A consistent care and handling regimen will help keep your rods in good condition and your operations running efficiently, giving you better results at lower cost.

DOWNLOAD PDF

Download the full PDF of Drill rod threads: tips to avoid common problems and improve productivity

DOWNLOAD

[pardot-form height="770" id="2405" title="Download Drill Rod Threads PDF"]