EXPLORATION

March 30, 2017

5 distinct advantages of industry’s next generation mobile underground coring drill rig

Boart Longyear’s MDR700 underground coring mobile drill rig is catching the eye of exploration drillers, mining house geologists and exploration managers alike. Fitting the bill as the next generation underground coring rig, Boart Longyear’s global product manager, Zac Strauss, talks through the advantages of the MDR700.

“The MDR700 is a powerful drill rig that delivers the reliability and versatility of our LM underground drills that customers value,’ said Strauss.

“What makes the MDR700 a truly next generation drill rig is that we have added technology to significantly enhance safety, increase productivity and improve ease of operation and maintenance.”

“The MDR700 delivers five distinct advantages that make it stand-out from other underground coring mobile drill rigs.”

1. Reduce The Risk Of Hand Injuries With On-Board Rod Handling

The MDR700 is the first and only underground coring mobile drill rig with an on-board rod handler. The risk of hand and back injuries associated with handling rods is significantly reduced on the MDR700. The rod handler sets new standards for ease-of use, versatility, and most importantly, safety. The rod handler isolates the driller from the hazards of manual rod handling.

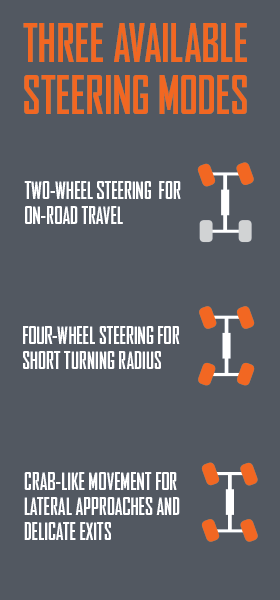

2. Achieve Un-Matched Manoeuverability With The Multi-Mode Four Wheel Steering

The mobility of the new MDR700 is a time-saver when moving from hole-to-hole using an agile Manitou diesel-powered four-wheel drive carrier. In a study where the rig was moved 500 meters (547 yards), the average time to move the MDR700 rig from hole-to-hole proved to be 80% faster than a regular underground exploration rig.

3. Drill Extremely Wide Angles For Greater Productivity

The next generation design of the integrated positioner and turntable offers extremely wide drilling angles and impressive reach to make positioning and drilling a series of holes easier. The rig features sophisticated articulations with eight movable joints so you can drill 270 degrees horizontally and vertically up to vertically down. The MDR700 also allows you to drill in a spherical manner without having to reposition the unit.

4. Enhance Safety And Productivity With DCi

The Drill Control Interface (DCi) provides semi-automation and a fully electronic interface to safely and efficiently operate both the rod handler and the drill. The DCi is a substantial step for increased safety on-site by moving the driller away from moving parts and hydraulic hoses – isolating the driller from the hazards.

5. Reduce Time Between Set-Ups With Exceptional Mobility

Set-up is quick and easy with the fully hydraulic positioning system and handheld remote controller. The MDR700 moves are faster and easier with the four-wheel drive diesel engine-powered Manitou carrier. Operating the MDR700 and the rod handler is smooth and easy when paired with the DCi. And the MDR700’s maintenance-friendly layout provides easy access for hydraulic servicing.

WANT TO KNOW MORE?

Download the MDR700 Mobile Drill Rig Technical overview PDF

DOWNLOAD

[pardot-form height="770" id="2397" title="Download MDR700 Technical Brochure"]

Media Permission: Boart Longyear grants you immediate agency to republish this article. We request that you cite Boart Longyear as the source and provide a link back where appropriate.