EXPLORATION

22 octobre 2018

Comprendre et prévenir la chaleur Vérifier la fissuration sur les tiges de forage

Qu'est-ce que la fissuration thermique?

La fissuration thermique est le terme technique décrivant la rupture fragile de l'acier, dans laquelle une mince couche superficielle est devenue excessivement dure et cassante à la suite de cycles rapides de chauffage et de refroidissement par friction.

Le réchauffement par friction résulte du contact ou du frottement avec la surface de contact. Une chaleur de friction peut s'accumuler pour dépasser la température de transformation de l'acier (ou «température initiale de transformation de l'austénite», ~ 750 ° C / 1350 ° F), suivie d'un refroidissement rapide à partir de l'acier ou du fluide de refroidissement environnant, d'un durcissement et d'une fragilisation. Lorsque ce cycle se répète fréquemment, le chauffage et le refroidissement créent une expansion et une contraction rapides qui conduisent à une défaillance en fatigue, perçue comme une fissure perpendiculaire se propageant depuis la surface.

Bien que ce phénomène soit bien documenté dans les textes techniques, le problème de l’industrie de l’exploration pétrolière et gazière est évident depuis les années 1940. L'API (American Petroleum Institute) décrit la fissuration par contrôle thermique comme suit: «Formation de fissures superficielles formées par le chauffage et le refroidissement rapides du composant». (API 'RP 7G-2, Pratique recommandée pour l'inspection et la classification des éléments de tige de foret usagés' et 'RP 96 - Conception et construction de puits en eau profonde'.)

Un document publié en 1992 par l'IADC / SPE sur la fissuration par contrôle thermique décrit des simulations à grande échelle pour démontrer que le chauffage et le durcissement sont faciles à obtenir, mais que la fissuration par fatigue ne résulte que du réchauffement et du refroidissement rapides associés à chaque rotation du train de tiges.

Comment la fissuration thermique se développe-t-elle sur les tiges de carottage filaire?

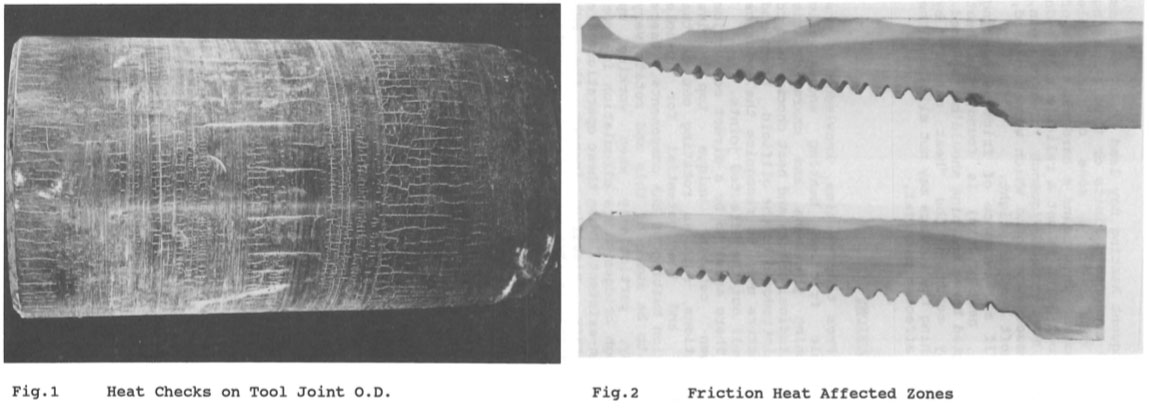

Comme le montrent ces images de tiges de carottage à câble, la fissuration thermique peut être facilement identifiée, visuellement sur le terrain. Les fissures thermiques sont uniques en ce sens qu’elles suivent l’axe de la tige (orientation longitudinale ou «axiale»), qu’elles sont situées près de l’épaulement de la tête femelle ou de la boîte, et qu’elles sont associées à une zone d’usure brillante et polie. Cette section de la boîte dépasse toujours un peu plus que toute autre zone sur une tige de forage à câble et se développe ou se gonfle sous des charges de forage élevées.

‘Box bulging’ is the result of a) the interference fit between the pin and the box (which is responsible for keeping the joint closed under deceleration ) and, b) the compression of the box shoulder under torsion and any radial loading from the thread-form. The positive load flank angles of traditional thread-forms, such as Q™ threads, generate radial load components that can increase box bulging to the point of separation, whereas premium thread forms with reverse-angle load-flanks, such as RQ™ and XQ™, actually limit box bulging.

Étant donné que les fissures thermiques résultent d'un chargement par fatigue, elles partent toujours de la surface et se forment perpendiculairement à la direction de la dilatation et de la contraction longitudinales ou axiales sur une tige de forage et passent facilement à travers les spires du filetage. Les ruptures en fatigue résultant de charges de forage excessives ou de déviations excessives produisent toujours des fissures qui commencent à l'intérieur et se forment perpendiculairement à l'axe ou de manière circonférentielle et suivent généralement le filetage. En d’autres termes, étant donné qu’il n’existe pas de charges de forage qui agissent de manière circonférentielle, le seul moyen de former des fissures longitudinales ou axiales consiste à chauffer et à refroidir rapidement.

En outre, considérez que la résistance à la fatigue de tout acier représente moins de 50% de sa "limite d'élasticité" normale et que l'acier trempé est beaucoup plus fragile que l'acier trempé. Lorsque soumis à une charge de fatigue excessive, la durée de vie maximale attendue de tout acier est inférieure à trois millions de cycles de charge alternée. En termes de tige de forage filaire en rotation, cela représente moins de quelques jours de fonctionnement, tout au plus. Cette même limite matérielle est à l’origine des ruptures en fatigue des joints de tiges de forage lorsqu’elles sont soumises à des déviations excessives (voir notre article précédent, «Capacités de cintrage de tiges de forage et applications de trous déviés).

Ces limitations sont valables pour toutes les qualités d'acier au carbone et allié de l'industrie du forage sur fil, tous les processus de formage de tube, tous les tubes à paroi variable et parallèle et toutes les configurations de traitement thermique. En effet, la température de transformation est déterminée par la teneur en carbone et n'aggrave pas de manière significative sans niveaux de carbone anormalement élevés (par exemple, la qualité AISI / SAE 1541 présente une teneur en carbone excessive et une température de transformation réduite, qui était une qualité courante avant le traitement thermique. est devenu populaire). En outre, qu’une tige de forage ait été initialement traitée thermiquement ou non, l’acier se transformera lorsqu’il est chauffé par friction au-dessus de sa température critique, quelles que soient les propriétés des matériaux précédents.

Figure 2 - Divers échantillons de tiges de carottage à câble avec durcissement et fissuration par contrôle thermique

De plus, ces limitations de matériaux sont valables, qu’une tige de forage soit neuve ou utilisée, c’est-à-dire que les propriétés de transformation ne changent pas avec l’utilisation. Les opérateurs qui souffrent de fissuration thermique ont souvent prétendu que leurs tiges anciennes ne craquaient pas, ce qui est une coïncidence. En d'autres termes, le risque de fissuration par contrôle thermique est déterminé par une différence dans la charge - éventuellement dans le même trou - plutôt que par une différence dans les tiges de forage.

Éviter les problèmes de fissuration dus à la chaleur

En résumé, la «fissuration thermique» résulte d'un problème d'application provoquant de la chaleur générée par a) une pression de contact latéral et, b) une lubrification insuffisante, entraînant une défaillance en fatigue.

Lateral contact pressure, or ‘drag’, can obviously be created with a misaligned drill rig or when the drill rod string passes through a deviation, but more typically is associated with drill string buckling, due to excessive drilling torque, rotational speed, and thrust or ‘weight on bit’. A reduction in any of these operating parameters will reduce the lateral contact pressure. However, in some cases drill rod midbodies may have been permanently twisted or ‘bent’, due to dynamic overload or due to roller rod handlers, which adds to lateral contact pressure. Always minimize fatigue and lateral loading by limiting hole deviation “dog-legs” (total deviation in dip and azimuth) to less than 1 degree per rod length, monitoring with tight hole survey intervals, and corrective reaming operations (limit to less than 0.6deg per rod in larger diameter holes). Avoid dynamic loading and rod twisting by maximizing spacing between multiple deviations and by eliminating neighboring deviations with opposing or divergent directions. Alternatively, select a free-cutting drill bit which will allow for reduction in torque and thrust. Use a Boart Longyear™ shoulder thickness wear gauge to inspect for un-even wear around the box shoulder circumference, which can provide an early warning to adjust operating parameters or improving lubrication.

Il est utile d’appliquer et de maintenir sur la surface extérieure du train de tiges un lubrifiant ou une couche de graisse appropriée pouvant directement réduire le facteur de friction et la chaleur générée. Pendant le tirage de la tige, inspectez visuellement l’usure du revêtement afin d’indiquer le degré de contact latéral. Des motifs d'usure «brillants d'un côté», soit aux extrémités de la boîte, soit avec un tour lent sur un quart de tour en spirale sur la longueur de la tige, indiquent une charge excessive.

Tandis que les fluides de forage contribuent au durcissement par contrôle thermique en trempant les surfaces chauffées, maintiennent une pression de fluide élevée et envisagent des additifs polymères pour améliorer la lubrification, ainsi que pour réduire le chauffage par friction et la trempe.

Enfin, considérons cette recommandation de l’IADC / SPE: «Lorsque les utilisateurs sont confrontés à la cause de l’échec, la réaction initiale est souvent l’incrédulité… Il est difficile de croire que les joints d’outil puissent chauffer au-dessus de leur température critique pendant le forage… en présence de circulation de la boue. De temps en temps, il est nécessaire de réintroduire sur le terrain la connaissance des phénomènes de chauffage par frottement dans le trou et de la trempe cyclique, ainsi que des fissures longitudinales caractéristiques. Les utilisateurs et les inspecteurs doivent reconnaître les preuves et éliminer les articulations touchées. ”

TÉLÉCHARGER LE FICHIER PDF

Téléchargez le PDF complet des filetages de tiges de forage: conseils pour éviter les problèmes courants et améliorer la productivité

TÉLÉCHARGER

[pardot-form height="770" id="2405" title="Download Drill Rod Threads PDF"]