SÉCURITÉ

14 février 2018

14 ans sans LTI à McArthur River

Boart Longyear Safety Milestone: 14 ans sans LTI

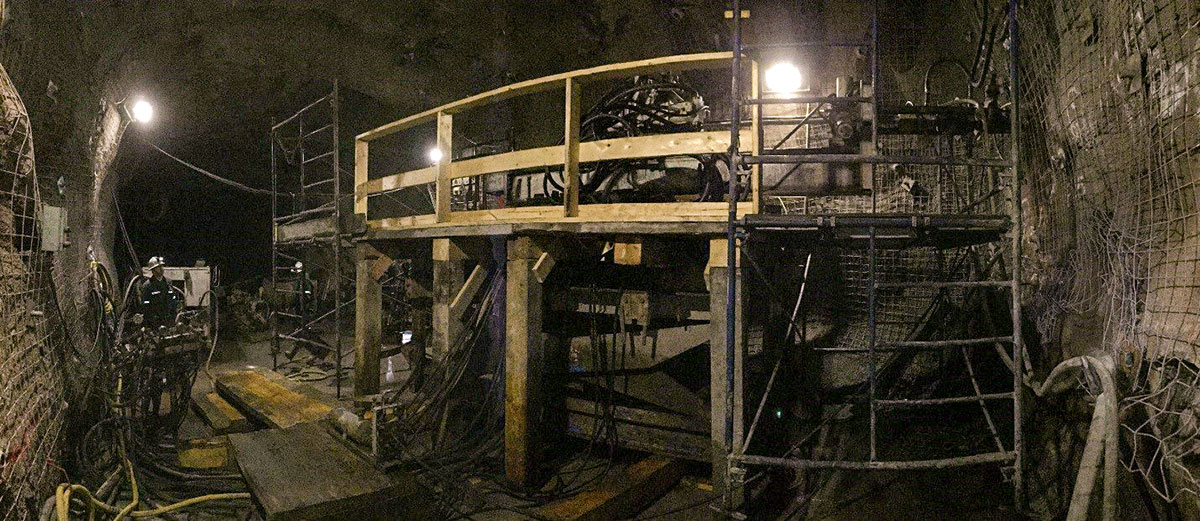

La mine Cameco McArthur River, située dans le nord de la Saskatchewan, possède le plus grand gisement d'uranium à haute teneur au monde. Boart Longyear a fièrement foré à la mine McArthur River depuis 1996. Situées dans le bassin d'Athabasca, les conditions du sol et de l'eau peuvent être extrêmement difficiles à la mine. La réussite de tout programme de forage nécessite des compétences, des connaissances et une solide culture de la sécurité, mais cela est particulièrement vrai à la mine McArthur River.

Appeler le travail à McArthur River spécialisé est un euphémisme.

Au fil des années, Boart Longyear a effectué de nombreux types de forage, notamment le forage de trous de gel et le forage de forets à nez bombé PWT. Il n’est pas inhabituel de forer à une profondeur de 120 mètres et à des creux de +90 'à -90', pour l’installation de tuyaux pour geler le sol. Imaginez trois couches de tiges de forage au diamant enrobées de ciment épais. Le sol est ensuite gelé afin que le minerai d'uranium puisse être extrait. De plus, un sur-carottage est effectué régulièrement pour retirer les tuyaux de congélation de la saumure.

Appeler le travail à McArthur River spécialisé est un euphémisme. En 2011, Boart Longyear s'est vu remettre le Cameco Innovation Award. C'était une reconnaissance de la technologie innovante dans "Une nouvelle application de la technologie de congélation pour isoler les zones minières". Aucun autre entrepreneur n'a reçu ce prix prestigieux à la mine.

Les conditions du sol à McArthur River peuvent être extrêmement difficiles. La cartographie du corps minéralisé et l'exploration des roches carottes ont été effectuées sous des forages pouvant atteindre 1 000 psi, empêchant ainsi le sol de se "coincer" sur le train de tiges.

Lorsqu'il s'agit d'uranium, 100% de l'eau doit être contenue dans le trou de forage et / ou le train de tiges. Les équipes de Boart Longyear sont formées à la protection de l'environnement souterrain tandis que le trou de forage produit 500 gallons d'eau potentiellement contaminée par minute à une pression hydrostatique pouvant atteindre 780 psi. La mise en œuvre et le suivi des procédures de sécurité et des règles ont été et seront toujours la clé du succès de l’exploitation minière.

Réviser les politiques et procédures en matière de sécurité et d’efficacité et créer une forte culture de sécurité étaient les objectifs premiers de la reprise des opérations à McArthur River par Jim Nelson en 2006. Ses années d’expérience et ses connaissances en matière de forage lui ont permis d’identifier et de mettre en œuvre les changements nécessaires. Rationaliser le projet pour la sécurité et la productivité n’était pas une tâche facile. Jim avait pour tâche de surmonter les problèmes d'horaire, les problèmes de personnel complexes et le manque d'organisation.

En écoutant les préoccupations de l'équipage et en travaillant avec eux pour leurs idées et leur adhésion, tout le monde a commencé à remarquer les changements. Le superviseur Brian Reister, qui travaille chez McArthur depuis 15 ans, déclare: «Les JSEA, les politiques et les procédures ont été élaborées autour du forage spécialisé à McArthur River». Avec le superviseur Jonathan Roy, qui a également travaillé chez McArthur pendant une bonne partie de la décennie, ont joué un rôle déterminant dans la promotion de la culture de la sécurité.

L’atteinte des 14 années sans incident avec perte de temps doit avant tout être attribuée à toutes les personnes qui ont travaillé à McArthur River au fil des ans.

La formation continue, les problèmes de sécurité, les incitations positives et le renforcement constant de la politique et des procédures ont responsabilisé l'ensemble de l'équipage pour ses actions et son succès. Une équipe de sécurité a été mise en place et tout le monde a travaillé dur pour créer un environnement qui tire le meilleur de l’autre.

L’atteinte des 14 années sans incident avec perte de temps doit avant tout être attribuée à toutes les personnes qui ont travaillé à McArthur River au fil des ans.

Tous les employés de McArthur ont changé leur comportement et ont adopté la culture de sécurité proactive sur laquelle Boart Longyear est fier. des règles d'or de sécurité et des JSEA, établies de longue date, à l'introduction plus récente de la roue de danger et au processus amélioré de FLRA axé sur la hiérarchie des contrôles.

Travailler en équipe est primordial à McArthur River; chaque individu se réunit pour développer des solutions afin de s'assurer que l'environnement de travail est non seulement sûr pour lui-même, mais pour tout le monde. Lorsque vous travaillez dans un environnement radioactif, il n'y a pas de marge d'erreur, la contamination met non seulement les individus en danger, mais également les moyens de subsistance de chaque personne sur le site.

En raison de l’environnement unique et dangereux, les matériaux et outils de forage traditionnels ont été remplacés par des produits spécialisés. Les équipes d’exploitation ont travaillé en étroite collaboration avec les ingénieurs de Boart Longyear pour mettre au point des contrôles destinés à éliminer les risques d’erreur humaine, tels que l’arrière-plan à verrouillage quadruple, afin de garantir le maintien du verrouillage du tube verrouillé.

Le Delta Clamp permet au LMTM150 pour percer et installer des tiges et des caissons surdimensionnés (tiges PWT, SWT, UW et 8 ”). Le système Anti-Goutte a été développé et installé pour éviter que la pince-pied et les mâchoires soient ouvertes en même temps à cause des mandrins manuels. La Kelly Valve, une autre innovation développée spécifiquement pour la mine, empêche la présence d'eau radioactive et le contact avec les employés lors du changement de tube, de l'ajout ou du retrait de tiges de forage.

Atteindre le cap des 14 années sans LTI a été un effort d'équipe. La participation, la collaboration et les contributions de tous les niveaux et départements de Boart Longyear doivent être reconnues. Au niveau du site, il s’agit des procédures quotidiennes allant des réunions de programmation, au suivi et à l’ajout de JSEA, à la réalisation d’évaluations de risques au niveau de l’équipe et d’individus. Tout le monde a un rôle à jouer dans le travail en toute sécurité. C’est à la fois croire et utiliser tous les outils et contributions que l’équipe de Boart Longyear a été en mesure de: Rendre sécuritaire. Faites-en personnel. Faire à la maison.