Sûr et conforme

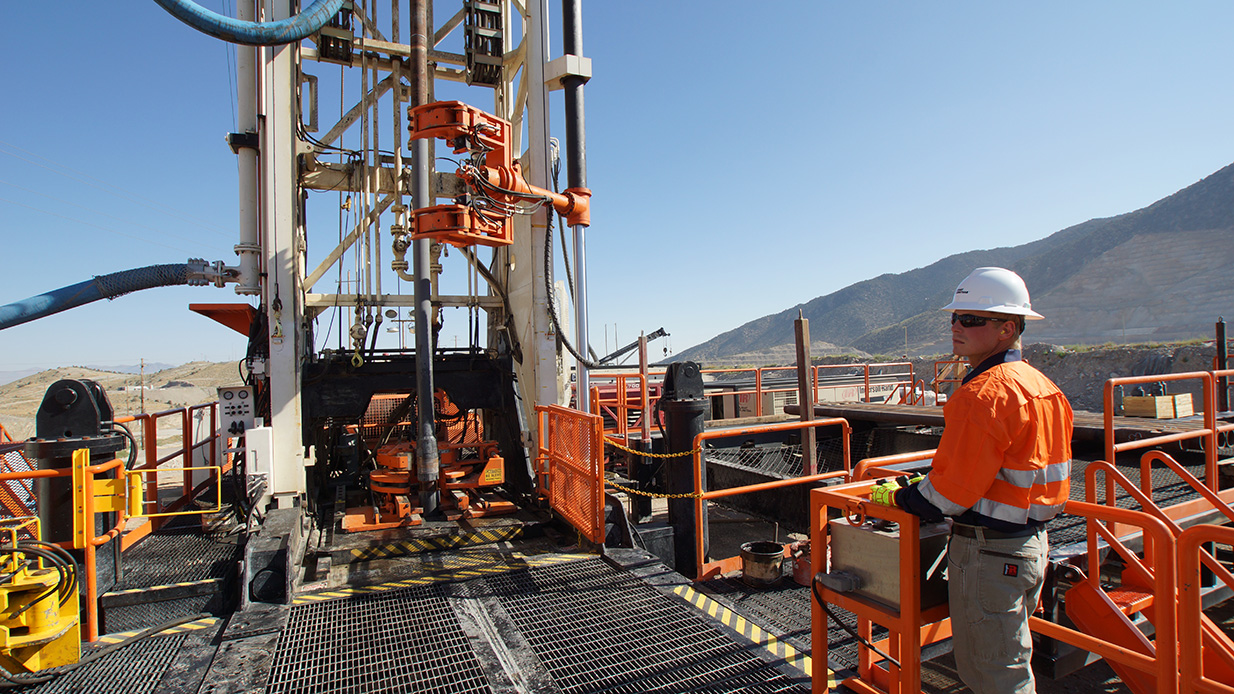

Vous avez besoin d'entrepreneurs de services de forage rotatif sûrs et conformes qui emploient les programmes de sécurité les plus progressifs et les plus efficaces, utilisent des innovations de sécurité conçues sur le terrain et cultivent une culture de sécurité où chaque employé sait que la sécurité est la priorité numéro un. Des programmes de sécurité et de formation de classe mondiale favorisent l'autonomisation et l'engagement des employés à tous les niveaux. Des programmes qui identifient et atténuent les risques pour une solide culture de sécurité.

Talent local, force mondiale

Vous avez besoin d’une main-d’œuvre locale et d’un sous-traitant de services de forage ayant une solide réputation en matière d’exploitation responsable dans les communautés où vous exercez vos activités. Global signifie que vous avez accès à la main-d'œuvre diversifiée de Boart Longyear, à des services interrégionaux et transversaux, à une expertise et à du matériel, ainsi qu'à des mesures et à des rapports globaux.

Service constant et fiable

Pour mener à bien votre prochain projet de forage rotatif, petit ou grand, faites appel à Boart Longyear pour son expertise technique, son expérience, ses installations de service et de fourniture mondiales et ses données de performance mesurables. Nous fournissons des solutions, une intégrité et des résultats grâce à notre service cohérent et fiable.

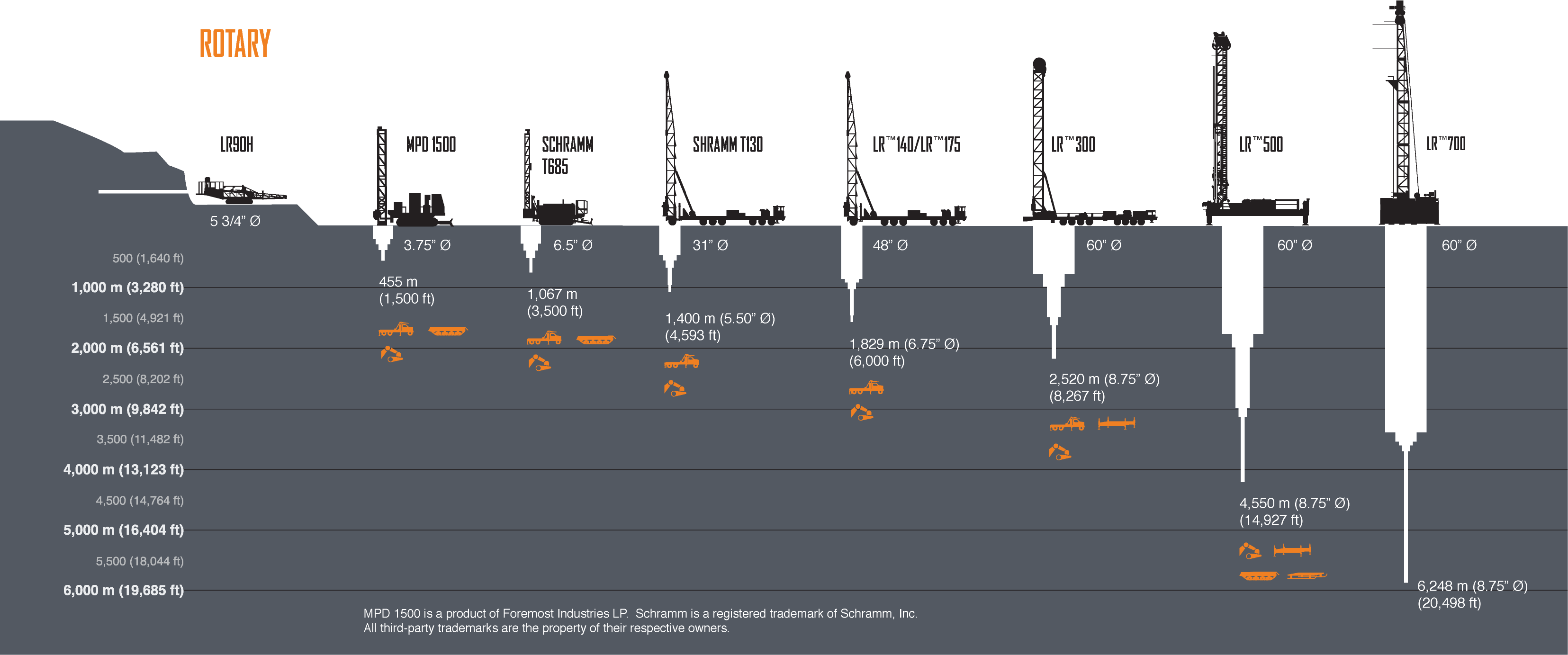

Flotte de gréements et d’équipements divers

En investissant en permanence dans le développement et la conception de plates-formes et d'équipements rotatifs efficaces et sûrs, vous pouvez compter sur Boart Longyear pour des profondeurs, une productivité et une disponibilité maximales. Les ingénieurs internes conçoivent et construisent des systèmes de forage rotatifs ultramodernes dotés d'une technologie de pointe, telle que l'auto-forage et la manipulation des tiges en mode mains libres. Les équipements Boart Longyear sont conçus pour la sécurité et sont testés sur le terrain pour la conformité et la fiabilité.

EXCELLENCE DE SÉCURITÉ

Boart Longyear s'est engagé à poursuivre ses investissements dans les programmes de pointe en matière d'environnement, de santé et de sécurité.

Solutions. Intégrité. Résultats.

Méthodes et capacités de forage rotatif

FORAGE DIRECTIONNEL

Boart Longyear est un fournisseur de services de forage directionnel à service complet. Notre vaste expérience technique et nos capacités directionnelles peuvent être utilisées pour percer des trous de pâte et des puits d’évacuation du méthane, des pré-colliers pour les alésages de forage et les puits d’eau, et occasionnellement pour l’exploration minérale. Apprendre encore plus >>

FLUIDES DE FORAGE AUTONOMES

Boart Longyear utilise un système autonome de fluides de forage dans lequel, lorsque les fluides de forage reviennent à la surface, ils sont collectés dans un réservoir où les déblais se déposent et le fluide de forage est ensuite réutilisé dans le processus de forage. Les réservoirs de fluides de forage autonomes garantissent un mélange et un entretien corrects des fluides de forage et permettent d'économiser de l'argent en éliminant le besoin d'une fosse. Le fait de ne pas avoir besoin d'une fosse pour forer des fluides est sans danger pour l'environnement, réduit la taille de la plaque de forage, peut nécessiter moins de permis de perturbation et élimine le besoin de remblayer.

FORAGE DE MARTEAU À AIR

Le forage par martelage pneumatique force l'air comprimé à travers la tige de forage à entraîner un foret à marteau pneumatique au fond du trou de forage. Le foret pneumatique frappe rapidement la roche et la pulvérise. Le forage à l'air ne ferme pas le trou de forage, ce qui permet d'obtenir des aquifères plus productifs que la boue rotative.

DOUBLE ROTARY

Dual Rotary maintient la stabilité du trou de forage en faisant avancer un cuvelage extérieur, ce qui permet de progresser dans les conditions de terrain les plus difficiles où les autres systèmes de forage de morts-terrains échouent. Une fois le boîtier en place, l'installation du puits peut être réalisée dans un environnement contrôlé.

DOUBLE TUBE INVERSE INVERSE

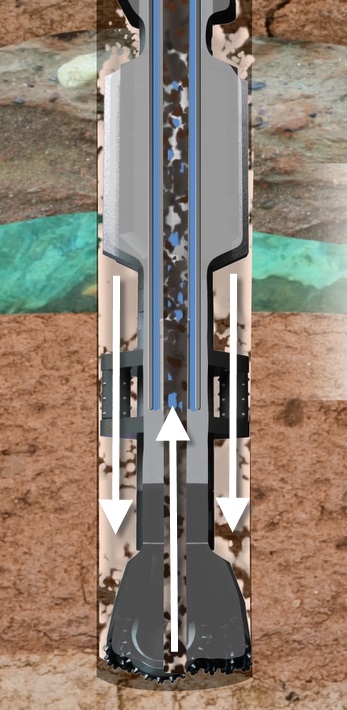

CIRCULATION INVERSE

Cette méthode de forage utilise un train de tiges à double tube. Le fluide ou l'air de forage s'écoule dans l'anneau intérieur du train de tiges, recueille les déblais au niveau de la face du trépan et remonte au centre de la ligne. Si vous utilisez un fluide plutôt que de l'air, le fluide est collecté à la surface où il est filtré et recyclé lors du processus de forage. Apprendre encore plus >>

Flotte de services de forage rotatifs

| Rigs | Se retirer | Taille de la tige de forage | Taille du trou | Angle Capable |

| DH I (Driltech modifié) | 90 000 livres | 5,5 "& 7" | 6 3/4" - 22" | Non |

| DH III (Driltech modifié) | 90 000 livres | 5,5 "& 7" | 6 3/4" - 22" | Non |

| T130XD (Schramm) | 130 000 livres | 5,5 "& 7" | 6 3/4" - 26" | Oui |

| LR™140 (Boart Longyear) | 140 000 livres | 5,5 "& 7" | 6 3/4" - 38" | Oui |

| T145 (Schramm) | 145 000 livres | 5,5 "& 7" | 6 3/4" 20" | Non |

| LR™200 (Boart Longyear) | 200 000 livres | 5,5 "& 7" | 6 3/4" - 31" | Non |

| LR™300 (Boart Longyear) | 300 000 livres | 5,5 ", 7" et 9 5/8 " | 6 3/4" - 60" | Non |

| LR™500 (Boart Longyear) | 500 000 livres | 6 5/8" | 8 3/4" - 60" | Non |

| LR™700 (Boart Longyear) | 700 000 livres | 6 5/8" | 8 3/4" - 60" | Non |

| Dépend de la taille du trou, de la taille du boîtier et de l'épaisseur de la paroi du boîtier (demandez un devis en conséquence) | ||||

Prêt pour la prochaine étape?

Soumettez une demande de proposition pour que Boart Longyear examine votre projet et soumette une offre pour fournir nos services de forage.

DEMANDE D'OFFRE

[pardot-form height="850" id="1557" title="Request for Tender"]