Superior Information

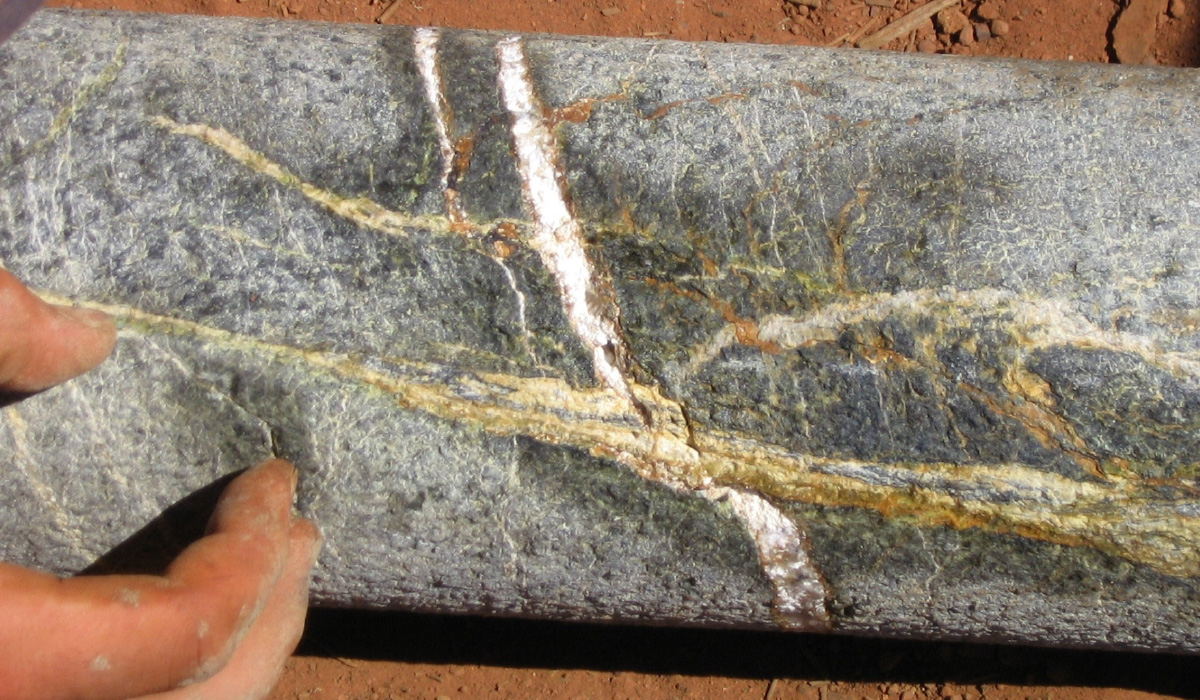

When you need superior information, sonic drilling provides a continuous, relatively undisturbed in-situ core sample of unparalleled quality and accuracy. During typical core barrel advancement, the core barrel is advanced 3.05 m (10 ft) using sonic frequencies. After the core barrel is in place, casing is sonically advanced over the core barrel. The core barrel is retrieved, producing a relatively undisturbed sample.

Reduced Waste Means More Meters for Less

Sonic drilling reduces drill spoils and waste by up to 80 percent relative to conventional drilling methods. Unlike drilling with an auger, virtually no cleanup is necessary with sonic drilling so you can drill more meters for less.

Faster than Conventional Drilling Methods

Resonant sonic energy is controlled by the driller to match the frequency of the formation and corresponds with the natural frequency of the drill string resulting in the maximum amount of energy being delivered to the sonic bit. At the same time, friction of the soil immediately adjacent to the entire drill string is substantially minimized, resulting in faster penetration rates.

Minimized Risk

Sonic drilling greatly reduces the risk of project failure due to unknown or difficult subsurface conditions. It also offers the flexibility of advancing a temporary outer casing as the borehole is drilled, meaning more can be accomplished with a single borehole. Outer casing minimizes the risk of cross contamination.

SAFETY EXCELLENCE

Boart Longyear is committed to ongoing investments in industry-leading Environmental, Health and Safety programs.

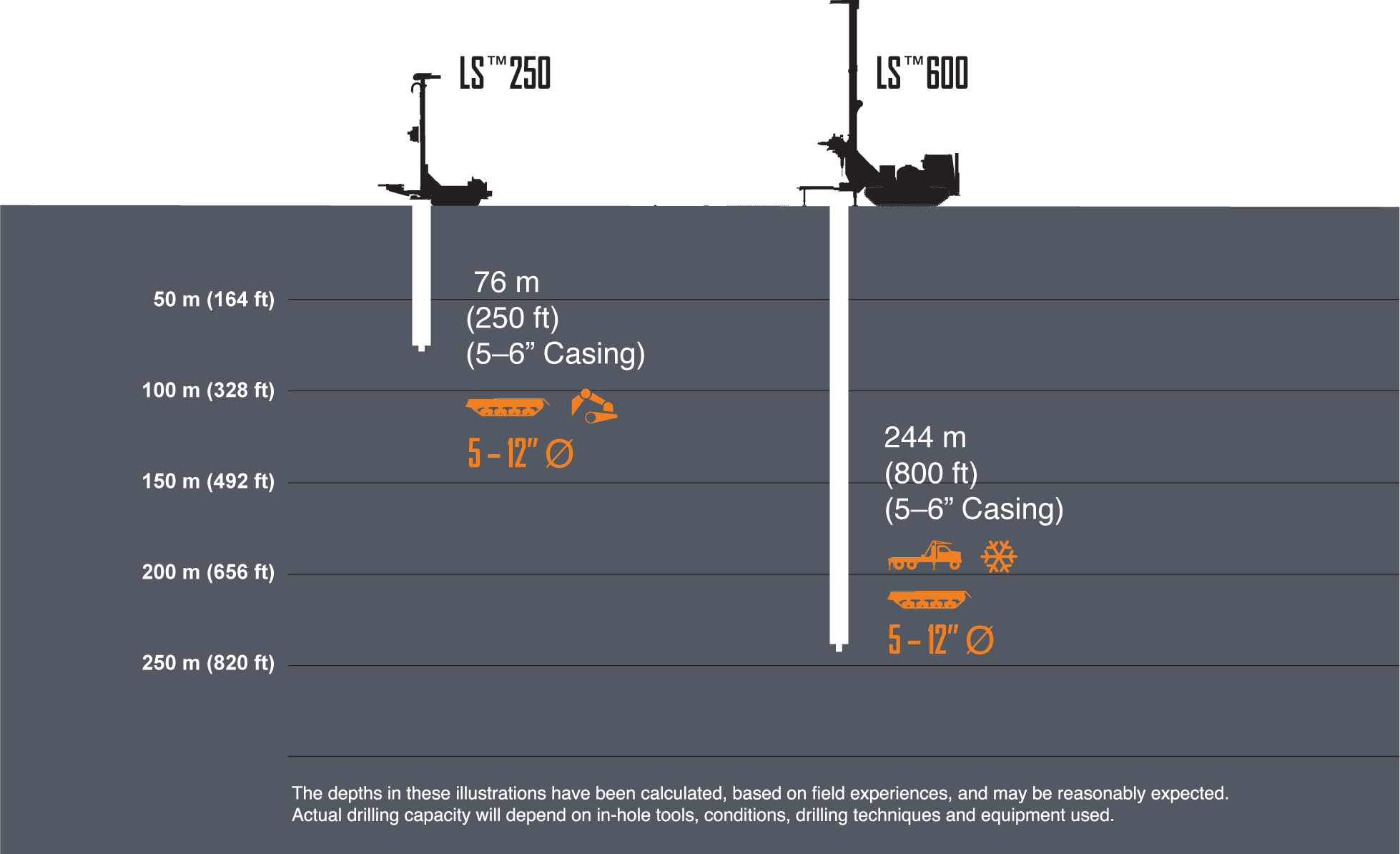

LS™600 Sonic Drill Rig

Sonic Drilling Capabilities

HEAP LEACH ORE RECOVERY

Ore that is not being milled is placed on pads underneath a sprinkler system that saturates the pads with a solution to wash the metals or minerals out. There are usually pockets within the pad that are unsaturated. We drill into that unsaturated portion to enable the solution to be delivered for leaching.

GRADE CONTROL SAMPLING

Ore that is to be milled is placed on pads that run through the mill. Prior to entering the mill, we drill into those input pads. The samples provided to the mining company give them a better understanding of the quality of ore output.

PRE-COLLARING

We drill through the dump material to set casing within the pile. Once the casing is set, this enables us to core below the dump material. Both Sonic and Rotary can be used in this application.

GEOTECHNICAL INSTRUMENT INSTALLATION

Geotechnical instrumentation installation that can be performed with sonic drilling include:

Vibrating wire piezometers

Slope inclinometers

Soil vapor probes

Standpipe Piezometers

Ability to adapt to CPT rams and push cones

WATER WELLS

Up to 10" water wells and depressurization wells down to 100 meters are achievable with sonic drilling.

Ready to take the next step?

Submit a Request for Tender to have Boart Longyear review your project and submit a bid to supply our drilling services.