EXPLORACIÓN

abril 12, 2017

El costo oculto de las barras de perforación más baratas

La sabiduría tradicional nos dice que un centavo ahorrado es un centavo ganado. Sin embargo, cuando se trata de comprar varillas de perforación, rasguñar monedas puede terminar incrementando sus costos de operación y poniendo en riesgo su reputación.

Debido a los importantes gastos relacionados con las barras de extracción de núcleos, es comprensible por qué muchos contratistas se centran en el precio de compra cuando intentan minimizar los costos. Para algunas decisiones de compra, eso tiene mucho sentido.

Pero, al igual que cuando compra un vehículo nuevo, es importante considerar más que sólo el precio. Después de todo, el costo "real" de ese nuevo vehículo brillante se reduce al costo por milla, y eso depende mucho de los hábitos de conducción, el consumo de combustible, las necesidades de mantenimiento, el potencial de averías y la calidad general del vehículo.

El siguiente es un resumen del informe: El costo oculto de las barras de perforación más baratas.

Descargue el informe completo para conocer más sobre la calidad, el uso de las mejores prácticas y el costo de operación y propiedad.

✕En nuestra industria, la medida comparable es el costo por metro. Y en realidad, la calidad de las barras, las condiciones del pozo y el uso operacional tienen mucho más que ver con el costo por metro de una sarta de perforación que el precio de compra inicial.

Aquí hay algo para considerar.

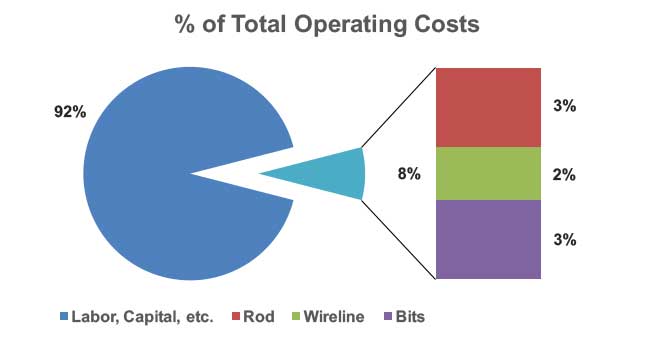

En una operación de extracción de núcleos de diamantes típica, los consumibles representan solo del 8 al 10 por ciento de los costos operativos de un contratista. La varilla corrediza es típicamente el 40 por ciento de esa cantidad, o aproximadamente el 3 por ciento de los costos totales.

Entonces, digamos que usted compra una barra de extracción de testigos que cuesta un 25 por ciento menos que un producto competitivo. ¿Estás realmente haciendo un ahorro? Tal vez no.

Antes que nada, considere el panorama general. Gastar un 25 por ciento menos en un 3 por ciento de su gasto de operación es realmente un ahorro de menos del 1 por ciento en general. En términos generales, entonces, el ahorro es bastante mínimo en relación con los costos operacionales totales.

Considerando que la manipulación y el uso de las barras de extracción de testigos durante la operación en terreno tienen un valor mucho más alto que el costo de compra, es importante mirar más allá del costo inicial.

Si variasbarras tienen la misma fuerza de unión, la decisión no debe basarse en el costo inicial sino en el menor costo por metro. Por ejemplo, una barra que es un 25 por ciento más cara pero dura un 50 por ciento más, realmente tiene un costo un 20 por ciento más bajo por metro, y eso puede sumar una gran cantidad de centavos ahorrados.

Más allá de la resistencia y durabilidad de la conexión, la forma en que un contratista maneja la barra en terreno tiene un gran impacto en la vida útil de la barra y las posibilidades de qeu la sarta se suelte, lo que a su vez afecta la productividad. Tener que volver a taladrar un orificio o lidiar con barras que no se conectan cuesta un tiempo precioso y puede afectar tanto los costos de operación como su reputación con su cliente.

Dadas las incertidumbres de las zonas de cizalladura, las formaciones de hinchamiento, los huecos y otras variables, incluso la técnica de perforación más precisa no puede evitar por completo las barras atascadas, así como una conducción cuidadosa no puede garantizar que no tenga un accidente en su vehículo nuevo.

Pero tener la varilla más fuerte posible aumenta tus posibilidades de poder salir del agujero sin romper las varillas y tener que pescar o perforarlas. Es como una póliza de seguro que le ahorrará costos operativos importantes al evitar más tiempo de inactividad cuando estas situaciones ocurren.

Entonces, si realmente quiere reducir al mínimo los costos y proteger su reputación, no rasguñe ni un centavo. Asegúrese de utilizar la barra más resistente y de mayor calidad posible, como la barra Boart Longyear RQ ™. Con un costo por metro menor que cualquier otra barra en el mercado, le ayudará a evitar problemas y ahorrar dinero a largo plazo.

DESCARGAR

Descargue la presentación completa para obtener más información sobre la calidad,

uso de mejores prácticas y costo de operación y propiedad.

DESCARGAR PDF

[pardot-form height="525" id="2199" title="Hidden Cost of Cheaper Drill Rod for new website"]

Permiso para los medios: Boart Longyear le otorga el permiso inmediato para volver a publicar este artículo. Le solicitamos que cite a Boart Longyear como fuente y proporcione un enlace de regreso donde corresponda.