Safe and Compliant

You need safe and compliant production drilling services contractors that employ the most progressive, effective safety programs, utilize field-designed safety innovations, and cultivate a safety culture where every employee knows safety is the number one priority. World-class safety and training programs promote employee empowerment and engagement at all levels. Programs that identify and mitigate risks for a strong safety culture.

Local Talent, Global Strength

You need local work forces and a drilling services contractor with a solid reputation for operating responsibly in the communities in which you operate. Global means you have access to the diverse Boart Longyear workforce, cross-regional and cross-functional services, expertise and equipment, and global metrics and reporting.

Consistent, Reliable Service

Let us help you achieve your production drilling objectives by providing industry-leading productivity, versatility in drilling at all angles, and a well-equipped maintenance facility and warehouse. Rely on Boart Longyear for our technical expertise, experience, and measurable performance data. We deliver solutions, integrity and results through our consistent and reliable service.

Diverse Fleet of Rigs and Equipment

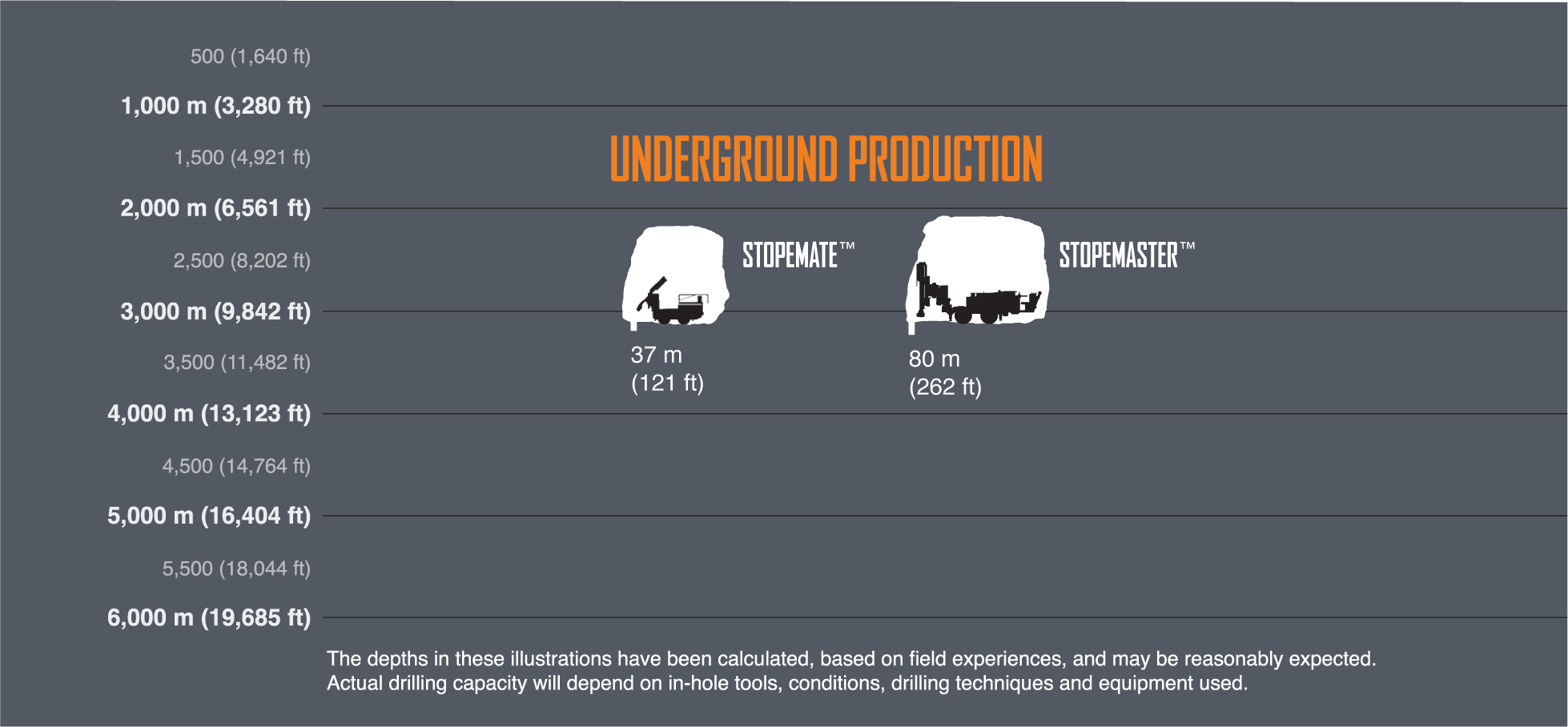

By continuously investing in developing and building new, efficient and safe production drilling rigs and equipment, you can count on Boart Longyear for industry-leading productivity rates and up-time. Boart Longyear uses modular designed rigs for decreased time to move rigs and increased productivity and our equipment is designed for safety and field-tested for compliance and reliability.

SAFETY EXCELLENCE

Boart Longyear is committed to ongoing investments in industry-leading Environmental, Health and Safety programs.

Solutions. Integrity. Results.

Production Drilling Capabilities

Boart Longyear offers a diverse range of underground production drilling services such as cable bolt drilling, long-hole drill and blast, and more. Our drilling service teams are dedicated to delivering safe, fast, and effective production drilling by using pneumatic/hydraulic down-the-hole (DTH) or top hammer methods.

SLOT AND INVERSE RAISES

Slot and inverse raises provide drill and blast holes from level to level in an underground mine. Boart Longyear uses portable drills and a time-tested methodology for cost effective meters.

LONG-HOLE DRILL AND BLAST

Used in both underground and surface applications in a pit, holes are drilled and explosives are then inserted to blast material, which is loaded and taken to the mill.

Boart Longyear offers:

• Pneumatic top hammer

• Electric/Hydraulic top hammer

• Conversion top hammer/ITH

• Hole Diameters from 51mm to 76.2 cm (2” to 30”)

• Hole Depths up to 90 meters (295 feet)

• Drill and blast veins as narrow as 0.3 meters (12”)

V-30 DRILLING METHODS

This lower risk alternative to conventional raise drilling and blasting provides improved fragmentation. V-30 creates a void and slot at the same time and eliminates the need for multiple holes. The V-30 drilling method creates free space for blasting. The method is a cost-effective alternative to raising and has proven to be faster than inverse or drop raises.

CABLE BOLT DRILLING

For cable bolt drilling, up-holes are drilled in the back of underground tunnels to install cables which are cemented in, providing structural support. Boart Longyear provides both the drilling and bolt installation for the convenience and time and cost savings of a single contractor.

Whatever your production drilling needs, Boart Longyear can recommend the most cost effective method for the fastest and straightest holes.

Ready to take the next step?

Submit a Request for Tender to have Boart Longyear review your project and submit a bid to supply our drilling services.