COMPANY

July 26, 2018

Exploring Solutions through Engineering

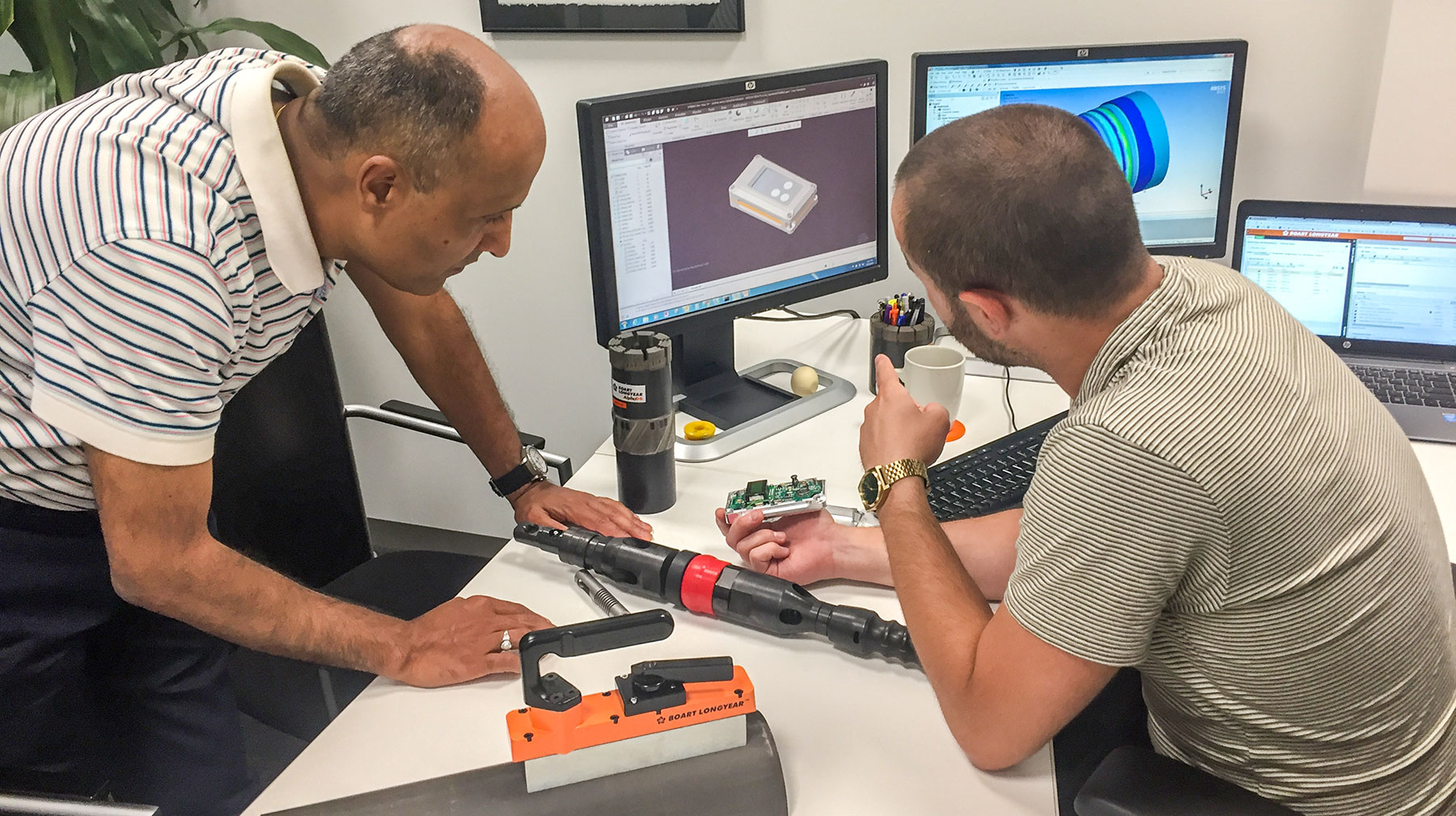

Every team aims to achieve a winning combination by leveraging the strengths of its individual members. Melding together a variety of skills, experience, mindsets, and even cultural backgrounds makes an ideal place for creative thinking and innovation to thrive. This is the reason that for over a century, Boart Longyear has placed great importance on cultivating a versatile global engineering team.

Currently employing nearly 40 engineers to design solutions for the resources drilling industry, Boart Longyear’s engineering team might be one of the company’s best kept secrets, although not on purpose.

It’s not a common business model, where a contract drilling services company also sells drilling products. But Boart Longyear does exactly that—the company provides a variety of professional drilling services to exploration and mining companies; it also designs, manufactures, and sells reliable drilling rigs, quality tooling, and accurate instrumentation.

Thanks to its team of engineers located throughout the world, the company is able to develop products and put them through rigorous testing in the hands of its own Drilling Services personnel. Tools and equipment are not only tested in the lab but also in the field. The collaboration between members of the global engineering team and Boart Longyear’s drillers elevates the performance of both Boart Longyear™ Drilling Products and Boart Longyear Drilling Services.

Some engineers are dedicated to Drilling Services projects – focused on developing solutions and safety innovations specifically for our contract Drilling Services teams. Other engineers are dedicated to developing solutions and safety innovations for commercialization for the Drilling Products division that then sells these products to the market. However, subject matter experts and synergies are leveraged across divisions for maximum potential as well.

Drilling Services brings technical issues or suggestions for improvements to engineers, who then research, design, and develop solutions. Solutions are also suggested by engineering –using the latest technologies, sometimes on problems that Drilling Services didn’t know they had. Engineered solutions are tested, tweaked to perfection, produced by our manufacturing team and implemented by Drilling Services.

The Drilling Products division focuses on designing solutions that help drilling contractors achieve more with less, safely. Boart Longyear drilling products are known for being high-quality products with proven results. The Products business works closely with Drilling Services to test new products before going to market. Products designs new bits, coring rods, in-hole tools, and production drilling tools and then uses Drilling Services to test, measure results for validation, and receive feedback. The engineering team generates valuable proprietary technologies which are instrumental to the global products business and protects those innovations with patents or maintains them as trade secrets.

This partnership between Boart Longyear engineers and Drilling Services benefits everyone in the industry as many of the solutions developed are also considered for commercialization. Boart Longyear Drilling Services uses the highest-quality, safest and most innovative equipment and tooling available, developed by Boart Longyear Drilling Products. As a result of the unique Boart Longyear business model and the collaboration with Drilling Services, Drilling Products customers know they’re using thoroughly tested equipment and tooling.

Here are just a few examples...

DCi increases meters drilled

Over a six month period (May – October 2013) Boart Longyear used an LM™75 drill rig with a Drill Control interface (DCi) to drill a total of 5,726.3 meters using a BQ™TK size diamond core bit. This was an increase of 907.7 meters drilled over the previous six-month average, which resulted in a unit cost improvement of $2.90 per meter average and monthly productivity increase of 13.5 percent. Read more…

New Longyear™ Bits Put 23% More Core in the Box

Using patented technology, the new Longyear™ bits have diamonds that are chemically bonded to the matrix creating a more versatile, faster penetrating, and a longer-lived bit. The new Longyear bits retain the smooth drilling characteristics drillers prefer, resulting in more core in the box on every shift for every crew. Available in 16mm more open, express geometry for even higher cutting speeds as well as 16mm Stage™ and 25mm Stage 3 configurations. Read more…

At Your Service: Customizing the new Stopemaster™ MDR in Canada

Recently, a mining client in Canada requested that Boart Longyear develop a mobile drill rig to solve the issues faced in moving their existing operating StopeMaster™ equipment safely and quickly through the mine. Read more…

LF™160 Surface Coring Drill Rig

Boart Longyear combined proven technology from its most popular surface coring drill rigs to create the powerful LF™160 which was fully tested and vetted with Drilling Services prior to commercialization.

When paired with the FL262 FREEDOM™ Loader, the LF160 combination is ideal for targeting sophisticated surface drilling exploration contracts that stipulate some of the highest safety standards, without compromising on productivity. Learn more…

Learn more about Boart Longyear Products or Drilling Services

Download the Boart Longyear Products and Drilling Services overview PDFs.

DOWNLOAD

Media Permission: Boart Longyear grants you immediate agency to republish this article. We request that you cite Boart Longyear as the source and provide a link back where appropriate.