OPERATING MINE

November 7, 2017

Check your buttons: Proven tips for more meters per bit

This article originally appeared in International Mining's November 2017 issue (requires subscription password)

Drilling contractors and mining companies rely on their tooling to get the highest productivity and the lowest cost per meter for every project.

When purchasing top hammer button bits, for example, choosing a high-quality product designed for the specific ground conditions is only the first step to achieving more meters per bit. Ensuring bits are properly used and maintained is critical to realizing a high return on investment.

Why Button Bit Wear is Important

When a top hammer button bit is sharp, the percussive energy transferred into the rock is at its optimum, resulting in effective rock fracture and a maximum penetration rate for the given drilling parameters.

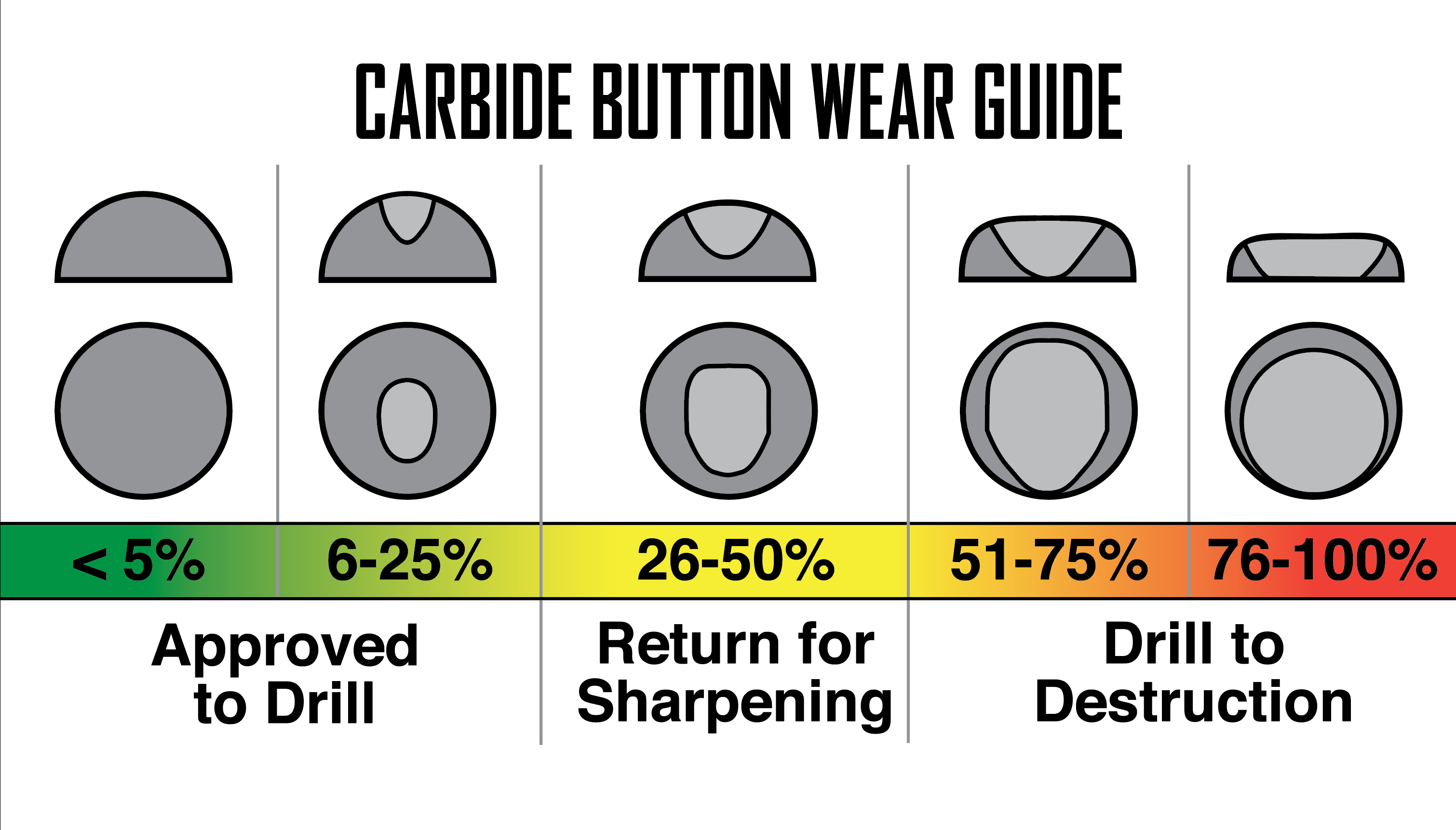

As flats develop on the buttons (tungsten carbide inserts), energy utilization is no longer optimized, leading to a lower penetration rate and reduced productivity. As buttons wear, the bit is less effective at fracturing the rock and the energy is dispersed over a larger surface area. Instead, rock is ground, rather than cut, producing smaller cuttings and energy (no longer used for breaking virgin rock) is reflected back up the drill string. This reflective energy contributes to increased loads on the tooling, drifter, and rig. As a general guideline, refurbishing the buttons before the flats reach 1/3 of the button diameter will maintain penetration/productivity, provide maximum bit utilization and help extend the life of all drill string components.

If the button flats are allowed to develop further to where they are considered over-drilled, productivity and the rate of penetration deteriorates. In this situation, much of the rock in contact with the buttons is re-drilled and the steel bit face may make contact with the bottom of the hole. Fewer and smaller rock chips are produced and much of the energy is reflected back up the drill string. This sacrifices the life of all the drill string components is a major contributor to hole deviation, increases wear and tear on drill rig components and results in higher operational costs overall. Top hammer button bits that are over-drilled exhibit broken buttons and impact drilling productivity.

Button bit wear patterns vary depending on the type of ground and the drilling parameters:

Gauge Wear

If drilling through hard materials such as sandstone and quartzite, drilling with excessive rotation, the wear tends to be greater on the bit circumference. Thus, when the buttons are sharpened, the diameter across the gauge is less than or equal to the diameter of the bit body. In this situation, the bit tends to bind (gauge-out) in the hole. Drillers should consider bit replacement or restoring the gauge button-to-body gap to the original (new) condition.

Harder ground conditions and drilling with excessive rotation creates wear that tends to be greater on the bit circumference.

Body Wash

When drilling in non-abrasive materials, carbide wear is minimized and drilling intervals are possibly longer. This allows for continued chip removal around the bit and wears away the bit body quicker than the carbides also referred to as body wash. Similar wear occurs in fractured and loose formations where constant hole cleaning and re-drilling of the materials is required for stabilizing the hole and to keep the hole open during retraction. To prevent button loss or shearing under these conditions, the protrusion should be reduced to the original height by scheduling grinding intervals.

Body wash often occurs when drilling in non-abrasive materials.

Over Drilling

The detrimental effects of over drilling button bits may not be immediately apparent. However, running dull bits not only slows down drilling rates but escalates costs by reducing the life of the drill string components, the rock drill and the rig components. Premature button bit insert failures are substantially reduced when over drilling is eliminated and correct sharpening procedures are performed.

Premature button bit insert failures are substantially reduced when over drilling is eliminated and correct sharpening procedures are performed.

Recommendations

To get the most out of top hammer button bits, training drillers and mining management on bit care, maintenance and identifying excessive wear can increase the return on investment.

1. Inspect Bits Frequently

Understanding the ground conditions and regular inspections of a button bit are necessary to prevent over drilling. To ensure optimal performance and life, bits require sharpening before the flat exceeds 1/3 of the button diameter. Working with a technical representative is recommended to establish specific guidelines since the maximum suggested wear before reshaping will depend on the button profile.

Drilling in non-abrasive ground can give rise to ‘snakeskin’ (small cracks) on the button surface. If it is not removed by grinding, button fatigue failure occurs.

2. Grind Protruding Inserts

Drilling in non-abrasive rock results in the bit face wearing faster than the inserts. Excessive insert protrusion, lacking sufficient steel support, can easily break while drilling and when retracting the bit from the hole. To prevent this from occurring, grind the buttons to restore the protrusion height.

3. Button Sharpening and Reshaping

If button protrusion is adequate, satisfactory re-sharpening can be achieved by use of a preformed diamond faced tool (‘cups’). Sharpening is performed by holding the tool firmly against the button and orbiting the machine in a circle to achieve a uniform surface finish. Diamond faced tools are designed to cut carbide and not steel. It is therefore recommended to have enough protrusion of the button from the face to avoid damage to the cup, bit or grinding machine.

Sharpened Bits =

• Faster penetration rates

• Less wear on drill string components

• Reduced tooling fatigue failures

It is important to implement effective grinding tool management since the tool profile gradually changes leading to buttons that no longer match the desired shape. Technical representatives can assist by providing specific recommendations.

A “Bit” of Training

It is always important to care for and maintain tooling and equipment. Consider a “bit” of training for drillers on getting the most life out of the top hammer button bits. More often than not, drillers come to work to do their very best and everyone wants to improve. Provide them with an opportunity to better their drilling habits by sharing these tips.

From a complete selection of rods, bits, and shanks to couplings, adapters, and other accessories, Boart Longyear provides top hammer tooling solutions for any percussive drill and blast application for both surface and underground drilling.

For more information on Boart Longyear top hammer tooling, visit our webpage or download the catalog.

SAFETY ALERT: Use appropriate eye protection, masks and ventilation when grinding drilling bits. Grinding wheels and tungsten carbide inserts contain: Tungsten Carbide; Cobalt; Tantalum; Chromium; Nickel; Aluminum and Silicon. Grinding tungsten carbide inserts releases particles containing these elements that can irritate skin, eye, nose, and throat and can result in lung damage.

KEEPING YOUR TOOLING IN TOP SHAPE

Download the full guide Keeping Your Tooling in Top Shape to read more about bit wear patterns, product servicing, and best practice recommendations.