NON-MINING

January 12, 2017

Seven Tips for Getting the Most Out of Sonic Drilling

Advanced sonic technology and highly trained sonic drillers

Advanced sonic technology and highly trained sonic drillers can reach depths of over 700 feet while obtaining near 100 percent in-situ core samples. Boart Longyear’s Fred Hafner offers 7 tips to get the most out of sonic drilling.

1. Know when to use sonic drilling over other methods.

Knowing when and where to use sonic drilling over conventional drilling methods is critical to delivering cost effective results.

There are three main reasons to choose sonic drilling technology:

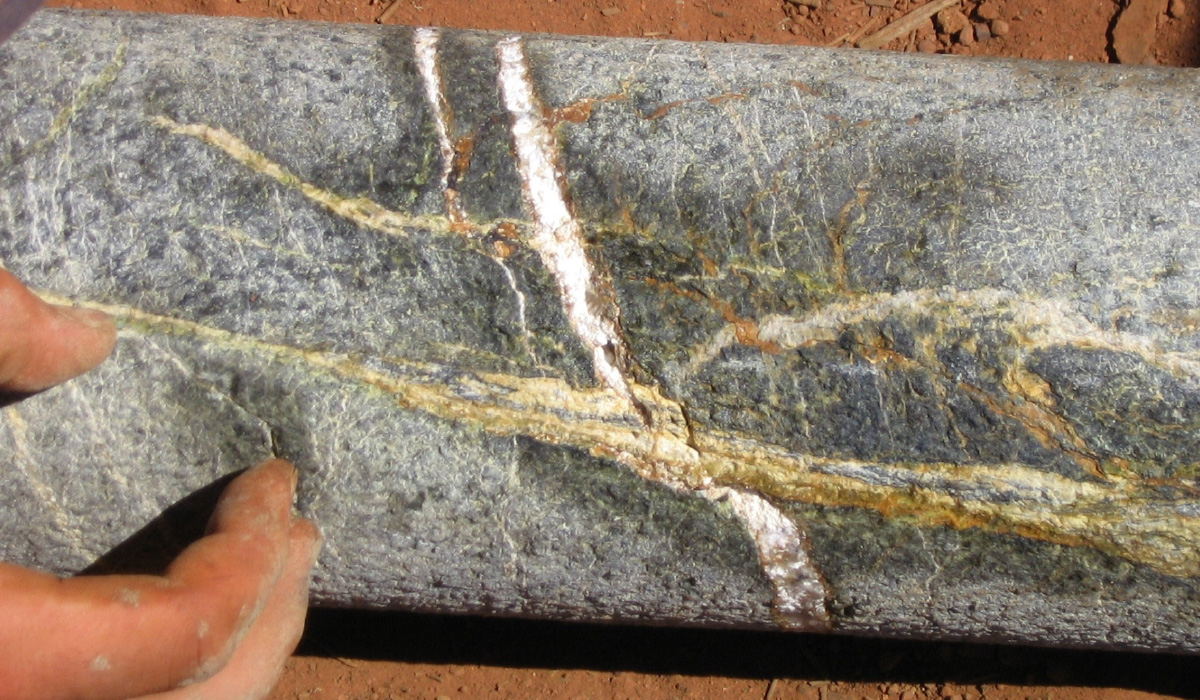

1. Projects that require a continuous in-situ sample to be collected — as opposed to reverse circulation (RC) drilling where chips are collected.

2. In situations that require avoiding fluid and air while drilling. No fluid or air is needed in sonic drilling, making it a good method for geotechnical, geo-construction, and environmental applications.

3. For projects where unconsolidated ground formations are encountered. Sonic drilling is a good solution because it can handle pebbles up to boulders while providing borehole integrity through a continuous casing process.

2. Choose the right drill bits and shoes for the ground conditions.

Ground hardness ranges from unconsolidated all the way up to 10 on the Mohs scale of mineral hardness. In unconsolidated ground, pay attention to the rock sizes and adjust the core barrel accordingly. For example, if rock sizes are 3 to 4 inches in diameter, the driller should select a core barrel that is at least 6 inches in diameter. Ensuring an adequate core barrel size allows for the drilling samples to pass through the core barrel for easy collection.

3. Telescope the core barrel to reach maximum depth.

Friction is the enemy. Telescoping the boring reduces friction to take the boring deeper. Core barrels should be sized to the casing size.

4. Don’t just watch gauges.

The best sonic drillers don’t just watch the gauges to know when to pull back or push forward. Experienced drillers running the sonic drill string, rely on their other senses; they can feel, touch, and hear how the drill string is progressing. Experienced drillers also rely on their knowledge of the drill site and ground formation. And the best drillers know when to adapt their methods as the hole deepens and encounters new ground formations.

5. Consider pre-collaring with sonic drilling for maximum efficiency.

When dealing with a couple hundred feet of overburden, pre-collaring with sonic drilling can be a more efficient way to reach the target depth. It is a quick and clean method that can also pull better information from the overburden — especially unconsolidated formations. Pre-collaring in sonic drilling provides an in-situ sample of the minerals and can better detect/protect against any water infiltration.

6. Engage and explain.

Although sonic drilling technology has been around for more than a couple of decades, the technology is still new to some. When the time is taken to engage with the customer and explain the process and technology, the benefits of the method are clear.

7. Keep safety top of mind.

Safety is the most important aspect to any drill site. Incorporate and promote a safety culture. Encourage drill crews to think before acting — take five minutes before doing anything. This allows the crew to focus on the task at hand, one task at a time.

Need to know more about sonic drilling? Read about the LS250 MiniSonic